What is a danger zone?

A hazardous area is a place where a fire or explosion may occur due to the presence of flammable gases or dust in the atmosphere. These sites include oil and gas facilities,

chemical processing plants and pharmaceutical manufacturers.

Hazardous area classification

The hazardous area is defined as:

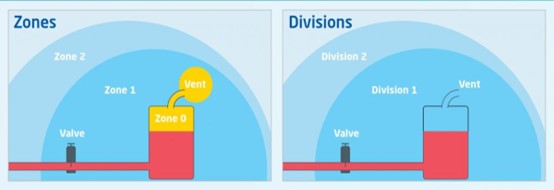

● "Zones" under global IEC standards (and their local versions, such as ATEX in Europe)

● "Division" under the North American NEC standard.

● Under the "zone" system, hazards are defined as Zones 0, 1 or 2 for gases, with 0 being the highest hazard, and as Zones 20, 21 or 22 for dusts with 20 being the highest

hazard.

● Under the “grading” system, gas hazards are defined as Class I Level 1 or 2, with 1 being the highest hazard, and dusts are defined as Class II Class 1 or 2, with 1 being the

highest hazard.

The classification of zones and zones is related to the frequency and duration of the possible presence of flammable gases or dusts in the atmosphere.

●Zone 0/20:>1000 hours/year

● Zone 1/21: 10 to 1000 hours/year

●Zone 2/22:<10 hours/year

● Class I and Class II Division 1: >10 hours/year

● Category I and Category II2: <10 hours/year

Codes and Standards

Depending on where you are in the world, different codes and standards may apply. Generally, regardless of the scheme, they cover the hazard classification and protective

methods that may be used to prevent explosions in these areas.

● Worldwide: IEC defines the most widely adopted hazardous area standards.

● In Europe, ATEX solutions strictly follow IEC standards

● In North America: NFPA (National Fire Protection Association) is the primary agency for protecting facilities from fire and explosion.

Recognized methods of explosion protection

For an explosion to occur, three conditions must be met:

● Explosive substances are present in appropriate concentrations

● Presence of air or oxygen

● Ignition source

Therefore, most forms of explosion protection and protection rely on eliminating one or more of these factors. For example, prevent leaks or spills of flammable materials,

or eliminate sources of ignition.

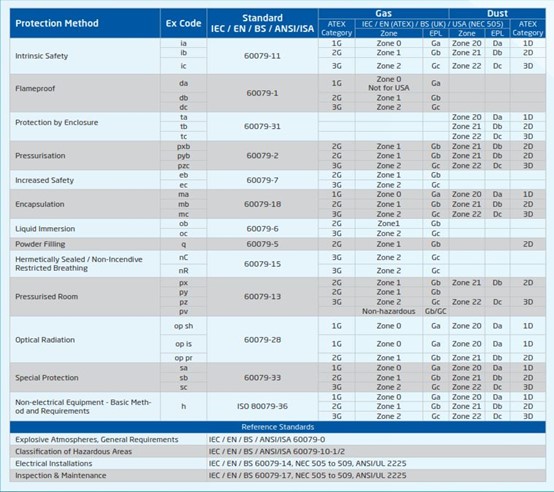

There are many recognized methods of explosion protection according to different codes and standards.

The table below shows the methods under the IEC/ATEX scheme.

The table below shows the method according to North American requirements.

Classification of flammable items

Gases and dust are classified according to their nature. These properties include factors such as ignition energy, autoignition temperature, upper and lower explosion limits,

flash point, etc.

Definitions vary between each group.

Temperature classification

A temperature classification (also called a temperature class, or T-class) defines the maximum surface temperature at which products used in

potentially hazardous environments are allowed to operate in ambient temperatures from -20°C to +40°C.

All flammable gases have an autoignition temperature. If a flammable mixture of gases is exposed to components above the autoignition temperature, the mixture will ignite.

Therefore, when selecting equipmen tThe temperature rating must be below the auto-ignition temperature of the potentially explosive atmosphere in which it will be installed.

- Products

- Motor Purge Systems

- Enclosure Purge Systems

- Hazardous area label printers

- Room Pressurization Systems

- Nitrogen Buffer Systems

- EPS Environmental Protection System

- Accessory

- Enclosure Purge Systems

- Projects

- Motor Purging System

- Enclosure purge system

- Room Pressurization Systems

- Nitrogen Buffer Systems

- Ex p Solution for Robot Arm

- Accessory

- News

- Celebrating the 70th anniversary of EXPO - Asia Pacific Celebration and product knowledge training was held in Qingdao

- Friendly Reminders and Required Compliance

- Comer Mechanical and Electrical 2024 Yangzhou group construction tour

- EXITING THE EUROPEAN UNION SANCTIONS

- Bribery Act 2010 2010 CHAPTER 23