IECEx, ATEX & UL certified purge and pressurization systems for Zone 2, Class I Div 2 applications

Features

Global approvals

Purge flow capacity up to 900 Nl/min

Leakage Compensation or Continuous Flow

Stainless steel enclosure construction

Expo’s Minipurge type Z range provides a full purge and pressurization solution for electrical enclosures and other equipment installed in Zone 2 or Class I Div 2 hazardous environments. Physically the same, Y purge systems are for use in Zone 1 / Class I Div 1 hazardous environments where the equipment to be protected already carries Zone 2 or Class I Div 2 certification.

With a range of flow capacities up to 900 Nl/min, the systems are suitable for large enclosures up to 5.4m3 volume. Expo also supply customised purge systems to suit higher flow rates. Y and Z purges are manually operated, with the user responsible for ensuring that the purge is carried out for the specified time.

Two configurations are available – Leakage Compensation (LC) and Continuous Flow (CF).

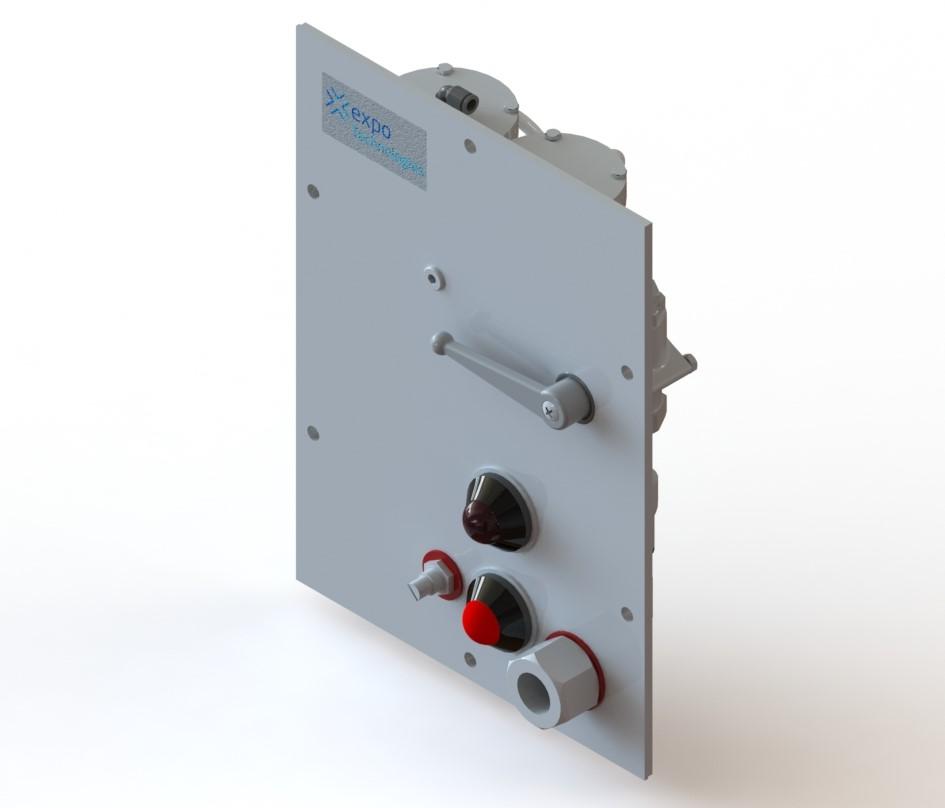

The system comprises:

Control Unit (CU) – The CU contains the pneumatic logic to monitor and control air flow and pressure, and provides the system outputs.

Relief Valve (RLV) – For systems with the LC configuration, the RLV measures purge flow at the outlet and provides over-pressure protection for the enclosure. For CF systems, the RLV provides over-pressure protection only

Spark Arrestor Unit (SAU) – For CF systems only, the SAU provides an outlet for the continuous flow of purge gas and provides flow measurement.

| Air Inlet | Instrument quality air,4-8 barg |

| Purge flow rate | Size1-225Nl/min Size2-450Nl/min Size3-900Nl/min |

| Purge mode | Leakage compensation (LC) or Continuous Flow (CF) options |

| Purge timer | Manually controlled |

| Timer power source | IS (Intrinsically Safe) Battery |

| Signal outputs | Low pressure alarm Options: IS outputs, pneumatic outputs |

| Certifications* | IECEx, ATEX, INMETRO, KOSHA, EAC, FM, cULus |

*Not all certifications apply to all system variants. Check the specific Operating and Maintenance Manual for details.